Coal has the ability to store large amounts of gas, because the surface has the ability to synopsp gas. Although coal is solid and looks like a hard rock, there are many pores that are smaller than the micron scale, so coal is like a sponge. It is this condition that causes the coal surface to become so wide that it is able to absorb large amounts of gas. If the gas pressure is higher, then the ability of coal to sponsor gas is also greater.

Coal-trapped gases consist mostly of methane gas, so it is commonly called Coal Bed Methane or abbreviated CBM. In the energy classification, CBM includes unconventional energy (rank 3), together with tight sand gas, Devonian shale gas,and hydrategas. High quality gas (rank 1) and low quality gas (rank 2) are considered conventional gases.

CbM production

in the coal seam is a lot ofcleats, which are formed during the process of burning. Through the hunk that water and gas flows in the coal seam. The part of coal surrounded by the hunk is called the matrix (coal matrix),the place where most CBM sticks to the pores contained in it. Thus, coal seam on CBM exploration targets in addition to acting as a reservoir, also serves as a source rock.

in the coal seam is a lot ofcleats, which are formed during the process of burning. Through the hunk that water and gas flows in the coal seam. The part of coal surrounded by the hunk is called the matrix (coal matrix),the place where most CBM sticks to the pores contained in it. Thus, coal seam on CBM exploration targets in addition to acting as a reservoir, also serves as a source rock.

Figure 1. CBM production principles

CBM can exit(desorption)from the matrix through the cremation, by lowering the water pressure on the target layer. The relationship between the quantity of CBM stored in the matrix to the pressure is called the Langmuir Isotherm curve (the process is at a constant temperature against pressure changes). To obtain CBM, production wells are made through drilling from ground level to the target coal seam. Because in the soil itself the coal seam is under high pressure, then the effect of pressure reduction will arise when groundwater around the coal layer is pumped (dewatering)upwards. This will cause methane gas to detach from the coal seam that traps it, and will then flow to ground level through the production well. In addition to gas, large amounts of water will also come out in this production process.

CbM potential regarding

the formation of CBM, then based on organic geoscience research using carbon stable isotopes numbered period 13, it can be known that there are 2 types of formation patterns.

the formation of CBM, then based on organic geoscience research using carbon stable isotopes numbered period 13, it can be known that there are 2 types of formation patterns.

Most CBM is a gas that is formed when there is a chemical change in coal due to the influence of heat, which takes place in the depths of the soil. This is called the thermogenesis process. As for CBM in the brown coal (lignite) layer located at a depth of less than 200m, methane gas is formed by the activity of microorganisms located in the anaerobic environment. This is called the biogenesis process. Both thermogenesis and biogenesis form, gases trapped in the coal seam are called CBM.

CBM quantity is closely related to coal ratings, which increase in quantity from peat to medium volatile bituminous,then reduced to anthracrate. Of course the quantity of gas will increase if the coal seam gets thicker.

From steven and hadiyanto research, 2005, (IAGI special publication) there are 11coal basinsin Indonesia that have CBM, with the top 4 reserve sequences as follows: 1. Sumsel (183 Tcf), 2. Barito (101.6 Tcf), 3. Kutai (80.4 Tcf), 4. Sum-Central (52.5 Tcf). In other words, CBM resources in Sumsel are equal to total (conventional) gas reserves throughout Indonesia.

Regarding the potential of this CBM, there are 2 interesting things to note:

First,if there is a conventional gas reservoir(sandstone)and a CBM(coal)reservoir at the same depth, pressure, and volume of rock, then the CBM volume can reach 3-6 times more than conventional gas. In other words, CBM attracts quantity.

Second,the principle contained cbm is adsorption in coal matrix,so in terms of exploration of success factor is high, because CBM can be found in both antiklin and sinklin. It can easily be said that there is coal there CBM.

CBM Production & Drilling Technology

In conventional CBM production methods, economical production can only be done on coal seams with good permeability.

In conventional CBM production methods, economical production can only be done on coal seams with good permeability.

But with advances in directional control techniques on drilling, the direction of the drill hole from the surface can be determined freely, so that elongated drilling in a coal seam can be done. As shown by the image below, gas production can be increased in volume through a single borehole using this technique.

This technique also enables the production of gas economically at a location that has so far been unenedable, related to the permeability of its poor coal seam. An example is what is done in Australia and some other countries, where efficient gas production is carried out with production systems that combine vertical and horizontal wells, as seen in the image below.

Furthermore, there has also been the idea of a multilateral production system, namely a production system that optimizes the technique of controlling the direction of the drill. Lateral referred to here is a well (drill hole) dug horizontally, while multilateral is a horizontal well that is divided into many branches.

In production where the surface location is constrained by the limitations of the installation of facilities due to being in the mountains for example, then the cost of production allows to be pressed when using this method. Practice, for example by integrating surface facilities.

Note: Drill direction control

technique Drilling technique that uses a down hole motor (in this mechanism, only bits attached at the end of the down hole motor only rotate, through the work of pressurized fluids sent from the surface) and not rotary drill machines (in this mechanism, bit turnover is caused by the rotation of drill rods or rods) that have been commonly used, to drill horizontal wells etc. from the surface. In this technique, a tool called MWD (Measurement While Drilling)is installed at the back of the down hole motor,serves to monitor the direction of the drill hole and perform direction correction while continuing to drill.

technique Drilling technique that uses a down hole motor (in this mechanism, only bits attached at the end of the down hole motor only rotate, through the work of pressurized fluids sent from the surface) and not rotary drill machines (in this mechanism, bit turnover is caused by the rotation of drill rods or rods) that have been commonly used, to drill horizontal wells etc. from the surface. In this technique, a tool called MWD (Measurement While Drilling)is installed at the back of the down hole motor,serves to monitor the direction of the drill hole and perform direction correction while continuing to drill.

ECBM

ECBM (Enhanced Coal Bed Methane Recovery) is a technique to increase the take-up of CBM. In this technique, commonly used injection gases are N and CO2. Here, the results obtained are very different depending on which injection gas is used. The image below shows CBM production using N and CO2 injection gases.

ECBM (Enhanced Coal Bed Methane Recovery) is a technique to increase the take-up of CBM. In this technique, commonly used injection gases are N and CO2. Here, the results obtained are very different depending on which injection gas is used. The image below shows CBM production using N and CO2 injection gases.

When N is used, the results appear immediately so that the production volume also increases. However, because N can reach production wells quickly, the overall production volume becomes reduced.

When N is injected into thecleats, then the N level in it will increase. And since the concentration of N in the matrix is low, N will flow into the matrix. A portion of N that enters the matrix will stick to the pores. Because the number of adsorption N is less when compared to methane gas, then the matrix will be in saturated condition (saturated)with only a little N only.

Figure 8. Substitution of injection gas in the coal matrix

But that's not the case with CO2. This gas is easier to attach when compared to methane gas, so CO2 will prevent methane gas from sticking to pores. CO2 then immediately sticks to the place a lot. Thus, in the matrix there will be a lot of CO2 so that the volume of gas flowing through the cleats is less when compared to N. As a result, CO2 takes longer to reach the production well. In addition, because CO2 is more substitution of methane gas that is in the matrix, the rate of recovery (recovery) CBM also increases.

Potential of Coal Bed Methane (CBM) as an alternative energy in Indonesia

Coal bed methane (CBM) is a relatively new source of energy. This energy source is one of the renewable alternative energy uses. Metane gases taken from this coal seam can be used as energy for various human needs. Even from fossil fuels that are not renewable, this gas continues to be produced when the coal seam exists. Why? Let's talk about it a little bit.

As we know, coal in Indonesia reserves and production is quite promising. We can see in figure 1, where Indonesia belongs to the world's coal producer countries.

As the need for energy increases, both for electricity and transportation, developing countries such as Indonesia also need an alternative energy that can continue to be developed. We can see in figure 2, where the need for energy for power plants continues to grow. One of the world's most dominant power plants is from coal energy.

Figure 2. Energy consumption source for electricity consumption in the world.

Based on estimates from an institution in France, the world's energy consumption will still use oil, coal and gas as primary energy (figure 3). This project provides an overview of the importance of the role of fossil energy as renewable "must" energy. Words should be here may not make sense, because the energy is indeed consumable (not renewable). With technology, research and new thinking, a coal seam can provide a new energy in the form of gas that we can use.

The cbm form is the same as other natural gas. Can be utilized households, small industries, to large industries. CBM is usually found in non-traditional coal mines, which are underground, among coal's chunks.

To produce CBM, the coal seam must be well watered to the point where the gas is present on the coal surface. The gas will flow through the matrix and pores, and exit through the damage or openings found in the well (figure 4).

Water in the coal seam is obtained from the process of flogging and burning, or from the input (recharge) of water in outcrops and aquifers. The water in that layer can reach 90% of the total amount of water. During the logging process, moisture content is reduced, with an increased coal rank.

Figure 4. The link between coal seam, water and CBM wells.

Biogenic gases from subbituminus coal seams will be able to potentially become CBM. The biogenic gas occurs by the reduction of bacteria from CO2, where the result is methanogens, a harsh anaerobic bacteria, using available H2 to convert acetate and CO2 into metane as a product of its metabolism. While some methanogens make amine, sulfide, and methanol to produce metane.

Water flow, can renew bacterial activity, so that biogenic gases can develop until the final stage. At the time of maximum hoarding, the maximum temperature in the coal seam reaches 40-90°C, which is ideal for the formation of metane bacteria. The metane is formed after the current underground flow of water has existed.

When groundwater drops, the pressure on the reservoir drops, at this time CBM migrates to the reservoir from the source of the coal seam. The iteration of this event is the regeneration of biogenic gases. This event is triggered by the rise of groundwater or a layer of coal washed away by water. This gives an indication that CBM is an renewable energy.

Coal seams can be source rocks and reservoirs, therefore CBM is produced insitu, stored through the surface of the cremat, mesopore, and micropore (figure 5). The surface attracts gas molecules, so it is stored close by. The gas is stored in the hydraulics and pore system of the coal until the moment the water changes the pressure on the reservoir. The gas then exits through the coal matrix and flows through the chunks up to the well. The gas is often stuck in the retribuations.

CBM can also migrate vertically and laterally to interconnected sandstone reservoirs. In addition, it can also be through ssars andkahans. The minimum depth of CBM has been found 300 meters below sea level.

Gas trapped in the coal seam relies heavily on the position of underground water level. Normally, the height of the water is above the coal seam, and holds the gas in the layer. By lowering the water height, the pressure in the reservoir is reduced, thus releasing CBM (figure 6).

Figure 6. CbM well cross section.

At the first time of production, there is a phase where the volume of water will be reduced (dewatering) so that the gas that can be produced can increase. After this phase, stable production phases will occur. Over time, peak production will occur, this is the time when CBM production reaches its maximum point and will decrease.

The volume of gas produced will be inversely proportional to the volume of water. When the volume of gas produced is high, the volume of water will be reduced. After the production peak, there will be the next phase, namely the phase of production decline (figure 7). Like oil and gas production in general, such phases are common. However, as outlined, CBM can be updated.

Figure 7. Volume vs time in CBM production.

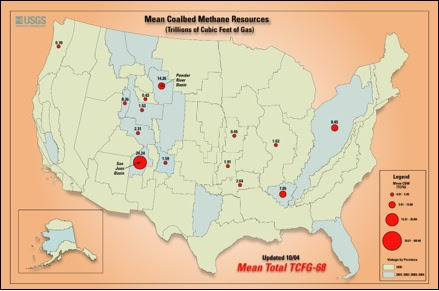

Indonesia's Coal Bed Methane (CBM) reserves are currently considerable, at 450 TCS and spread over 11 basins. The largest potential is located in Barito area, East Kalimantan which is about 101.6 TCS, followed by Kutai if 80.4 TCS. Compared to figure 8, Americans who have fairly extensive and scattered coal reserves, have only relatively small CBM reserves.

Based on World Bank data, the largest concentration of potential is located in Kalimantan and Sumatra. In East Kalimantan, among others, it is spread in Berau Regency with a content of about 8.4 TCS, Pasir/Asem (3 TCS), Tarakan (17.5 TCS), and Kutai (80.4 TCS). Regency of Barito, Central Kalimantan (101.6 TCS). Meanwhile, in Central Sumatra (52.5 TCS), South Sumatra (183 TCS), and Bengkulu 3.6 TCS, the rest are located in Jatibarang, West Java (0.8 TCS) and Sulawesi (2 TCS).

For information, the largest resource of 6.49 TCS is in sangatta-1 block with pertamina operator upstream methane energy Kalimantan A with basin in Kutai. Followed by Indragiri hulu with samantaka operator of prime minerals with South Sumatra basin which has 5.50 TCS resources, and the lowest resources are located in Sekayu block operated by Medco SBM Sekayo with South Sumatra basin, with a resource of 1.70 TCS.

Bantu berikan donasi jika artikelnya dirasa bermanfaat Anda dapat berkontribusi dengan mengeklik tautan di bawah ini:

Donasi Sekarang

Komentar